Typical capacity design factors DF range from 100 to 125 100 to 80 of theoretical maximum capacity. The conveyor is a 2000mm wide belt running at 56ms with an existing capacity of 6600tph.

Hollow and solid pin chain has an optional side plate design known as deep link.

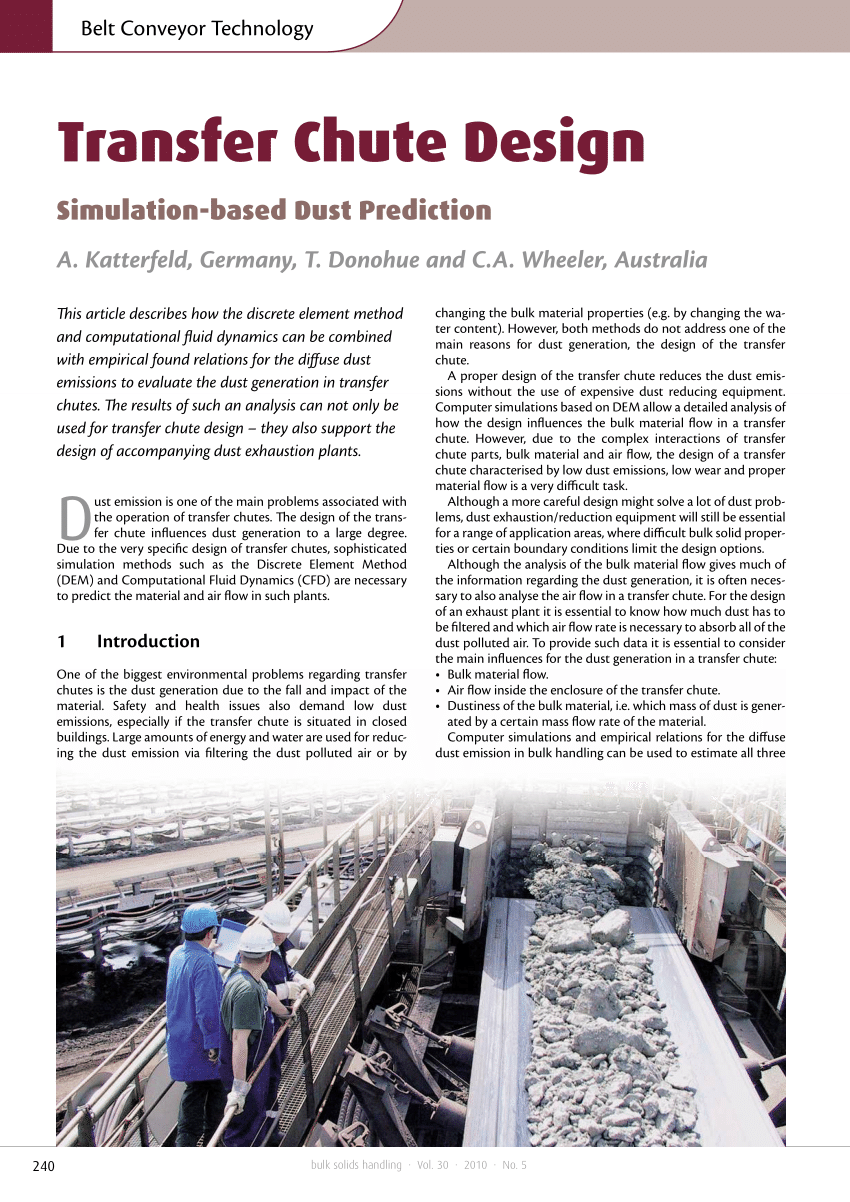

. And in chutes reducing risks to belt product degradation dust emissions and improving power demand. This paper presents the chute flow analysis for a granular cohesionless material in a hood and spoon style transfer chute and bench scale testing methods to calculate the coefficient of. INTERNATIONAL STANDARDS Conveyor chain like transmission chain can be manufactured to a number of different international standards.

In other cases transfer chutes are employed to direct the flow of bulk material from one conveyor belt to another often via a three dimensional path. We are qualified to take on even the largest of projects in the material handling industry. Itll come in several volumes theyll all be worth the read.

25 Transfer Differential Angle and Drop Height. Blocked chutes high wear of liner materials. SPECIALISTS IN CONVEYOR DESIGNS SYSTEMS and ENGINEERED FLOW CONTROL CHUTESES.

No eBook available. For Conveyor Belt Systems. Our Company has successfully completed a wide range of high quality Conveyor Designs and Chute projects.

Try the new Google Books Get print book. The text is based on the work of Dick Stahura of Martin Engineering and the First International Chute Design Conference sponsored by the Bionic Research Institute in South Africa. The importance of correct chute design to ensure efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear cannot be too strongly emphasised.

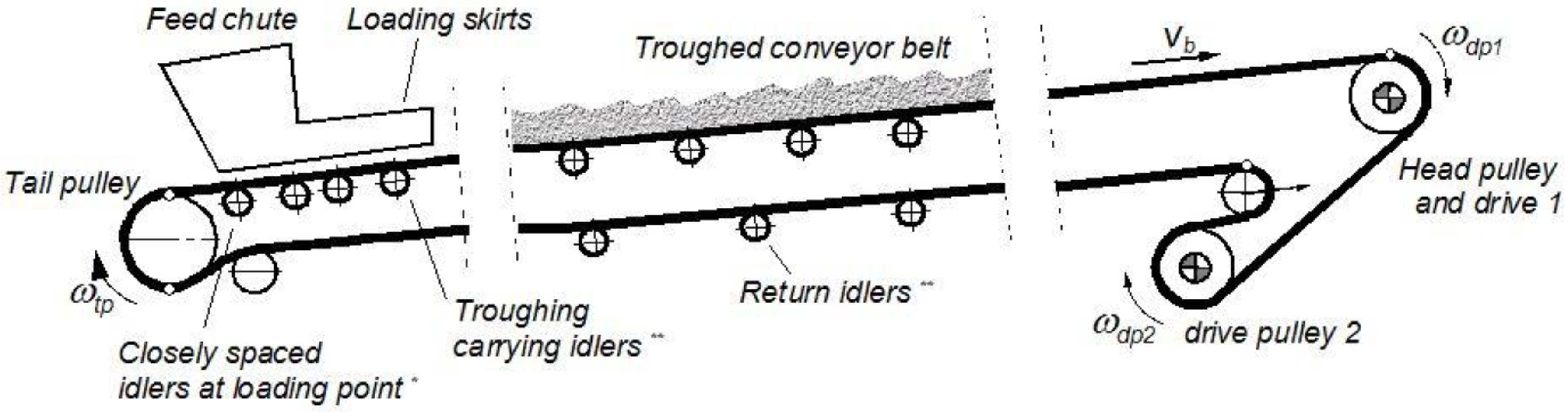

Trajectories and chute design are particularly important at transfers from. A Review by Em Prof Peter Arnold and Dr David Hastie Centre for Bulk Solids and Particulate Technologies Faculty of Engineering University of Wollongong. The frictional resistance of the conveyor components drive and all accessories while operating at design capacity.

Accurate calculation of the trajectory Maintaining control over the bulk material flow Controlling the bulk material stream velocities and dust generation Ensuring that the presentation of the material to. Used under hoppers or silos to transfer material to conveyors trains trucks or ships. One conveyor to another.

A new design hierarchy in step with designing conveyors that are not only of the proper capacity. In a continuous effort to improve the efficiency of processes the industry is bombarded with transfer chute problems that include. Hp T e V 33 000 -----.

The new procedures using analytic methods are compared with present conventional practices. INTRODUCTION Belt conveyor transfer chutes have not been duly appreciated nor has sufficient technology guided their design criteria. The type of material handled and its physical as well as mechanical properties are the principal factors determining the type and design of conveying equipment and its accessories.

Bulk materials include various heap-loaded granular and powdered materials such as coal ore molding sand saw dust food grains and so on. Download - Preview Embed. However the conveyor horsepower should always be calculated on 100 of theoretical capacity to accommodate starting under surge or head loads.

The Transfer Chute Design Manual For Conveyor Belt Systems. Here is no doubt that transfer chutes in conveying systems. The force required to accelerate the material continuously as it is fed onto the con-veyor by a chute or a feeder.

If you are author or own the copyright of this book please report to us by using this DMCA report form. Design of belt conveyors in a book written for technically qualified people. Conveyor Transfer Design Pty.

Clean Safe and Productive Conveyors by Design Chapter 21 In this Chapter In this chapter the traditional conveyor design hierarchy1. The frictional resistance of the material as it is being conveyed. We serve to meet all your Conveyor and Chute Design needs.

The Transfer Chute Design Manual For Conveyor Belt Systems By C Benjamin P Donecker S Huque J Rozentals. Transition distance is 5735m flat at the Tail pulley to 45 degree trough. Know-How Conveyors 5 Manufacturing 1 Draft available for comment We have a 50 page Word document first draft 300 kB.

They frequently point out that an effective chute design requires. The MHEA website says The two key Recommended Practice design guides for troughed belt conveyors chutestransfer points are now undergoing a strategic review Whatever that means. Published by the Conveyor Equipment Manufacturers Association.

The book we are all waiting for is the one written by Nordell Spriggs et al. Discharge at points other than the head pulley can be. For a given speed belt conveyor capacities increase as the belt width increases.

This chains side plates have greater depth than normal thus providing a continuous carrying edge above the roller periphery. Principles of chute design there are five basic design objectives to guide material on to a conveyor belt at the speed of the belt in the direction of belt travel to eliminate material spillage to enclose material dribbles to enclose material from operating personnel to eliminate dust liberation 3 current design philosophy chutes are transfer. Rozentals Director Bionic Research Institute 1.

Check out the new look and enjoy easier access to your favorite features. Minimum code compliance including safety and 3. This document was uploaded by user and they confirmed that they have the permission to share it.

The proper chute design is influence onto belt conveyor run in a stable position maximal load capacity and resulting high production throughput with. The belt trough angle at the feed is 45 degree with 3 roll idlers. Try the new Google Books.

RATIONAL DESIGN OF CONVEYOR CHUTES J. Download The Transfer Chute Design Manual For Conveyor Belt Systems. SUMMARY A review of Commissioning Reports has shown that detailers of conveyor chutes frequently lack understanding of basic theoretical and practical aspects of chute design.

The Transfer Chute Design Manual.

Pdf The Belt Conveyor By D V Subba Rao Perlego

Conveyor Material Handling Videos Brochures Power Roller Accumulation Belt Chain Transfers

Energies Free Full Text Specific Energy Consumption Of A Belt Conveyor System In A Continuous Surface Mine Html

Cema Belt Conveyors For Bulk Materials 7th Edition Published Date April 2014 With Metric Conversion Print For Conveyors Print Format Metric Conversions

Belt Conveyor An Overview Sciencedirect Topics

Belt Conveyors For Bulk Materials Fifth Edition Pdf Version

Conveyor Belt Screw Pneumatic Hydraulic Roller Chain Bucket Vibratory Inst Tools

0 comments

Post a Comment